Maximum Workpiece Size:720mm

Spindle Speed:24,000 RPM

Tool Capacity:24 tools

X/Y/Z Axis Travel:600mm x 500mm x 600mm

Precision Grade:ISO Class 3

Maximum Cutting Force:120kN

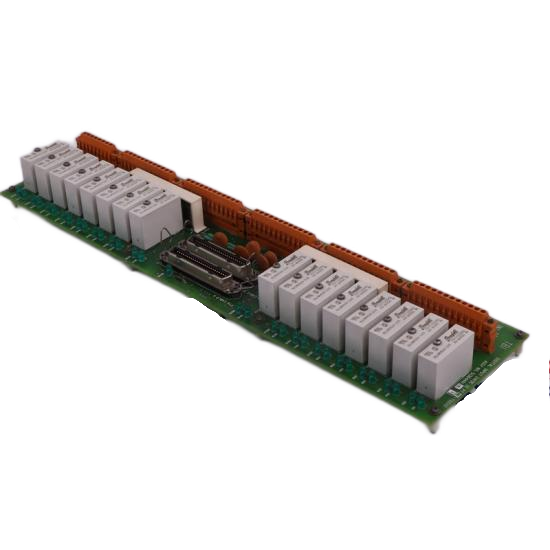

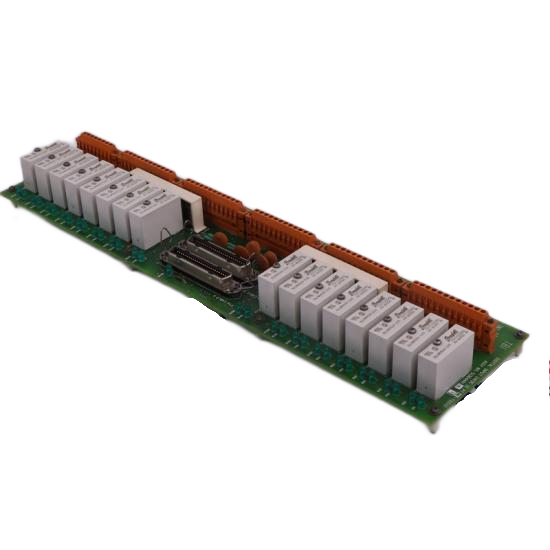

Electronics & Control System:Fanuc 0i-MF Control Unit

Coolant System:Fully Automatic with Overflow Prevention

The OKUMA ER-JG-7200D is equipped with a powerful spindle motor, delivering exceptional cutting performance and speed without compromising on precision. This CNC machine is designed with advanced cooling systems, ensuring efficient heat management during long machining processes.

Featuring a spacious worktable and a robust structure, the ER-JG-7200D is capable of handling heavy-duty parts with ease. Its modular design allows for customization to meet specific production needs, from single piece prototypes to mass production runs.

With an intuitive and user-friendly control panel, the machine supports a wide range of programming languages, including Okuma’s proprietary OSF and standard NC codes. This flexibility ensures that users can seamlessly integrate the machine into their existing production lines.

The inclusion of the MQL (Minimum Quantity Lubrication) and Flood coolant options provides a sustainable and efficient approach to part cooling and lubrication, reducing waste and enhancing machine longevity. These features are complemented by a comprehensive maintenance schedule, ensuring the machine operates at peak efficiency.

The ER-JG-7200D comes with a suite of safety features designed to protect operators and minimize downtime. These include automatic tool change systems, emergency stop functions, and real-time monitoring capabilities, ensuring a safe and productive working environment.

There are no reviews yet.